An automated test bench

for automotive gas injectors checkup

An electormagnetic gas injector is the basic metering

component of the 4-th generation automotive gas-fuel system.

†††††††††††††††††††

†††††††††††††††††††

The identity of the

gas injectors determines most of the basic specifications of the vehicle,

running on gas: exhaust gases composition, dynamics, idle stability, gas fuel

consumption.

The open status time

of the gas injector on practice is not definitely proportional to controlling electric

impulse duration. The time additionally depends upon many factors. Among these

are: pressure drop on the injector, coil inductance and active resistance, core

mass, spring resistance, the gap between the core and the seat, the injectors

orientation (deviation from vertical) and so on. The identity of these factors

must be ensured by the technology. On practice they differ from one injector to

another. This results in the dispersion of the behaviors of the injectors being

used jointly. The dispersion also depends upon the control impulse duration.

ThatТs why the gas injectors behaviors comparison should be executed in

dynamics only and in the conditions under which the injectors work on the

engine.† The basic conditions are

pressure drop presence and controlling electric impulses supply.

††††

††††

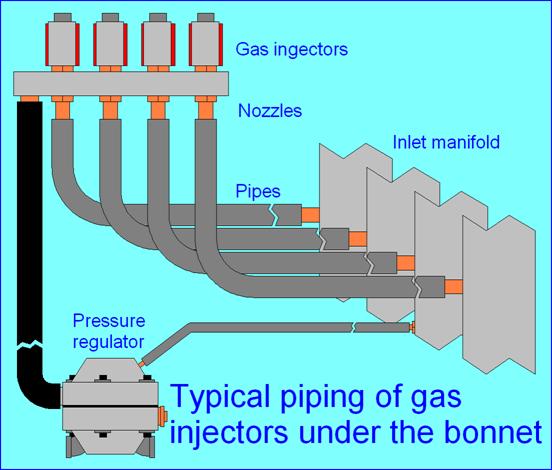

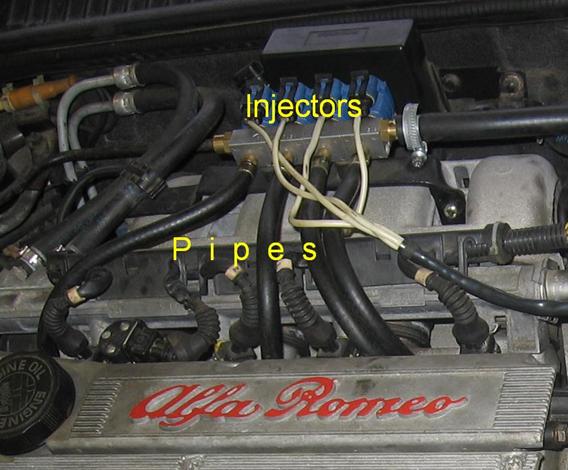

There are also some

more СexternalТ factors, that determine the injectors behaviors. The basic are:

- the length, the form and the cross

section of the pipes that connect the injectors and the inlet manifold;

- the angles under witch the pipes are

connected to the inlet manifold;

- the flow areas of the injectors outlet

nozzles.

These СexternalТ

factors differ in practice from injector to injector and from vehicle to

vehicle. ThatТs why the possibility is important to check the pneumatic routs

identities for each a cylinder on the way from pressure regulator to inlet

manifold. The gas injectors installed under the bonnet once are hardly

accessible after as a rule. It is difficult to extract them for checkup and to

install back then. So very desirable is the opportunity to checkup the

injectors without their extraction from under the bonnet. The defective injector

only can be extracted if detected and replaced or repaired.

So, it is obvious,

that compact, fast, highly productive, completely automatic, safety and

efficient equipment is needed to fairly check up the vehicle gas injectors in

every day work on auto-gas service.

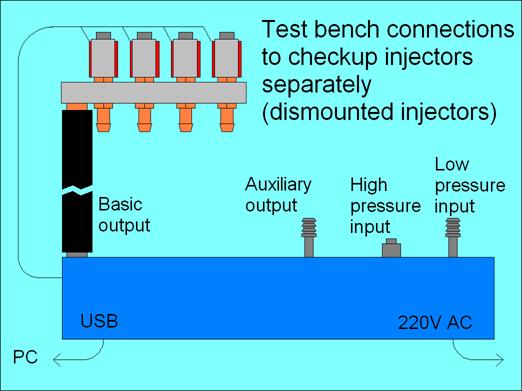

The test bench is

meant to checkup automotive gas injectors both alone and directly on a vehicle.

During the checkup both safe gas and electric control impulses are supplied to

the injectors.† The injectors run just as

under the bonnet and their supply characteristics are being directly measured

as gas consumption via electric impulse duration.† The characteristics curves are displayed on

the computer monitor and compared automatically. The dispersion of the

characteristics is automatically calculated and also can be estimated visually

from the screen. Also can be estimated the linearity of the supply

characteristics and the control electric impulse minimal duration to open each

the injector.

There is Сmotor modeТ

in the bench computer program. In the Сmotor modeТ the bench generates control

pulses for gas injectors in any desirable mode: sequential, synchronous,

coupledЕ In the Сmotor modeТ† the СloadТ

and the СrotationsТ can be delicately tuned via computer program controls and

the gas consumption is being continuously measured. A professional can detect

injectors characteristics dispersion even orally in this mode: the sound of the

injectors that run under pressure is loud and very distinctive. The Сmotor

modeТ can also be used in educational purposes to demonstrate both the 4-th

generation automotive gas system and gas injectors functioning.

1. The bench checks normally closed

injectors (closed with no electric current in coils).

†††

Coil resistance: 1 Ohm or more.

2. Working gas to be used Ц any safe and

non-aggressive gas:

††††††††† -

compressed air;

††††††††† -

compressed nitrogen;

††††††††† -

evaporated carbon dioxide.

†††

Electrical heater is present to use high input pressures and evaporated

carbon dioxide.

3. Input pressure:

††††††††† -

at high pressure input: 10-200bar;

††††††††† -

at low pressure input: 5-7bar with receiver volume 50liters or more and

pressure maintaining system.

4. Pressure at the basic output: 1bar.

5. Pressure at the auxiliary output: up to

7bar.

6. Electric control pulses durations

range: 1-25ms.

7. Checkup time for 4 injectors: 2.5min

(common mode); 6min (precise mode); 30min (high precision mode).

8. Sensitivity: 3 ranges for weak, common

and strong signals from injectors with various nozzles diameters.

9. Power supply: 1.5A 220V AC.

10. Personal computer to be used:

††††††††† -

windows XP;

††††††††† -

USB port;

††††††††† -

800X600 or better screen resolution.

To test new injectors

or ones dismounted from a vehicle. The pipe from the basic output being long

enough, mounted injectors under the bonnet can also be checked with these

connections.

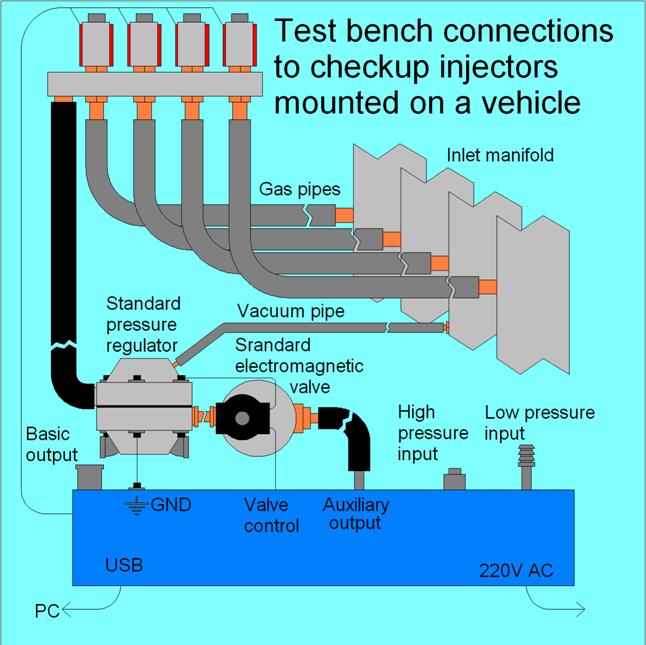

To checkup injectors,

mounted on a vehicle. Standard pressure regulator and standard gas supply

valve, mounted on the vehicle, are also used and so are also being checked:

1. Test bench inlets,

outlets and controls.

1 Ц heater LED;

2 Ц power ON LED;

3 Ц plug for injectors cable connection;

4 Ц high pressure input;

5 Ц low pressure input plug;

6 Ц basic output;

7 Ц auxiliary output;

8 Ц power plug;

9 Ц USB port plug;

10 Ц plug for standard gas valve control cable

connection;

11 Ц standard gas valve plug fuse;

12† Ц plug for

vehicle ground connection.

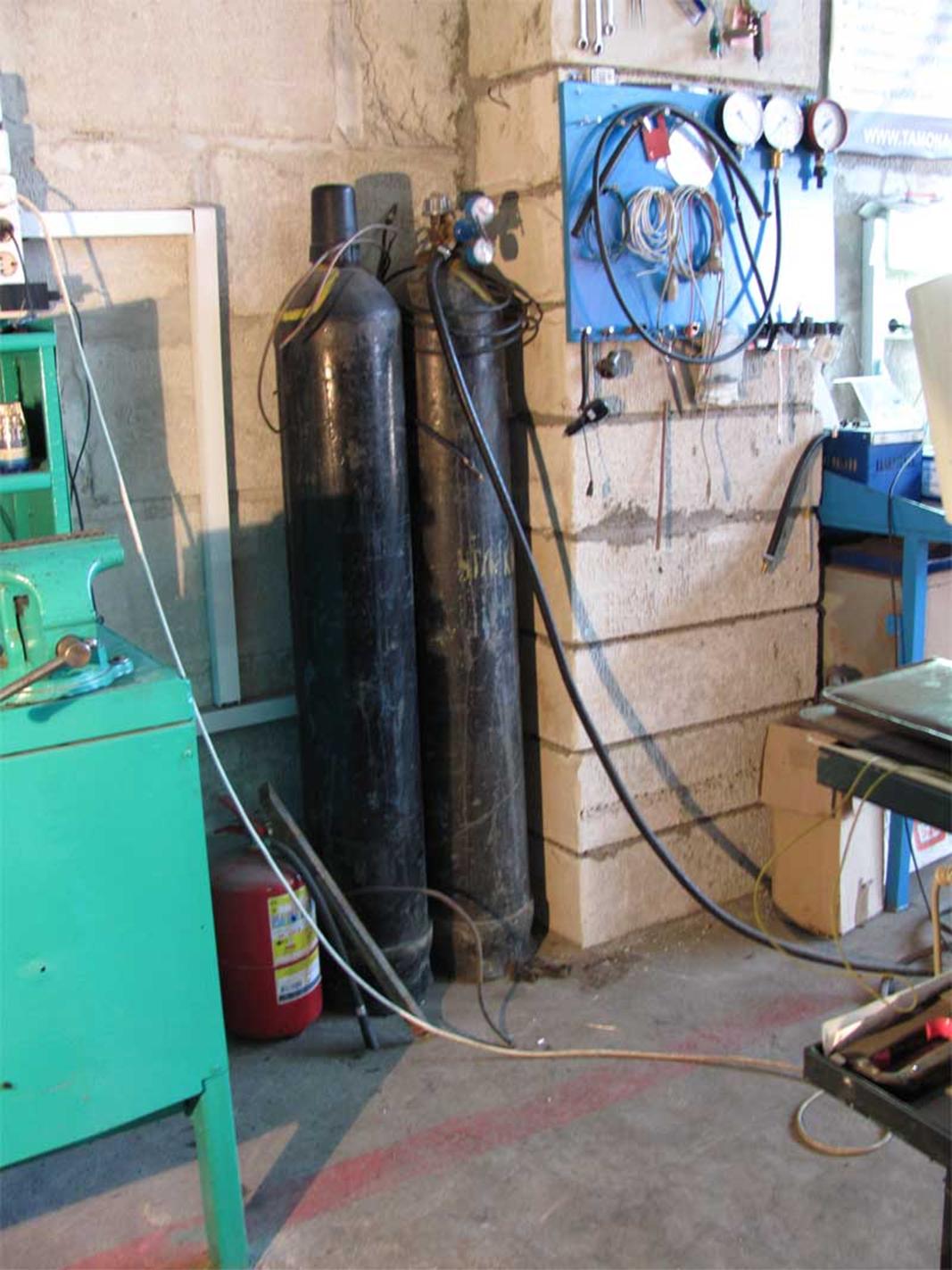

2. Test bench in use.

2.1. General view

2.2. Front view

2.3. Back view

2.4. Bottles with

carbon dioxide

1. Space

adjustment in 4-inj. rail.

Screen video. High resolution, sound.

Download video (24.1Mb )†††††††† Watch video (YouTube)

††††††† †††††The video detailed

description

E-mail: dze@bk.ru

Phone:

+375-293170994

Mikhail Dzahnidze